Our laboratory is certified to standard CSA W178.1 as a welding inspection organization in compliance with the requirements of the Canadian Welding Bureau. Our group of over 60 non-destructive testing technicians are certified to various standards such as CGSB, SNT-TC-1A, AWS, Loyds PED, API, CSA W178.2, BINDT, NACE etc.

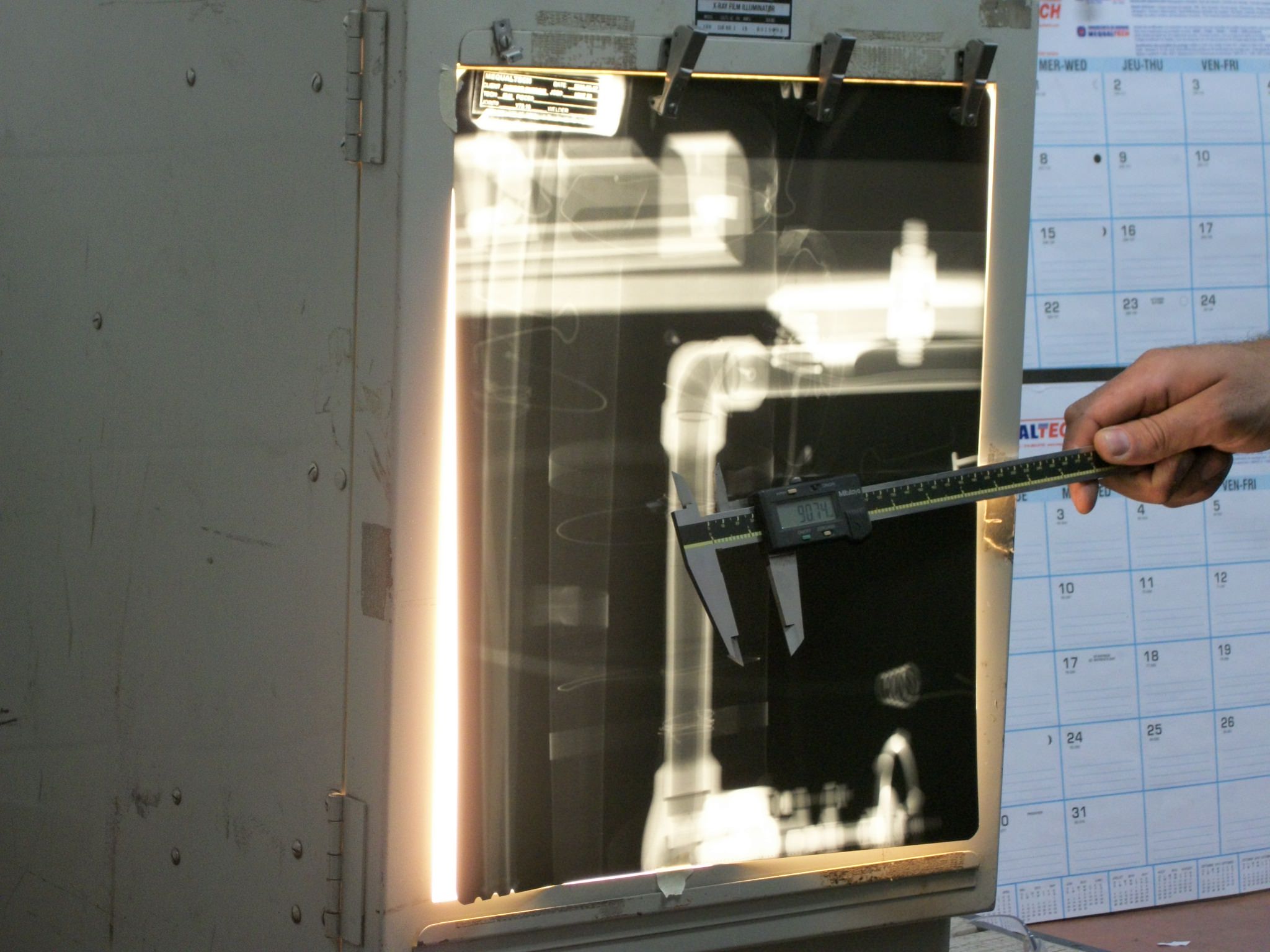

X-Ray / Gamma Ray Radiography

Similar to medical radiography, industrial radiography is a method used to detect flaws within materials and welds such as porosities, inclusions, cracks, lack of fusion, lack of penetration, etc.

Ultrasonic Testing

Ultrasonic testing is a method based on the transmission and reflection of ultrasonic waves which detect flaws within a material or a weld.

Dye Penetrant Inspection

Also called liquid penetrant testing, this capillary action based method is used to locate surface-breaking defects in metals, ceramics and other non-porous materials. DPI is widely used in numerous industries to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks, fatigue cracks, etc.

Magnetic Particle Inspection

Magnetic particle inspection consists of applying ferrous iron particles (either colored or fluorescent) to a ferromagnetic material into which is induced a magnetic field. Surface or subsurface discontinuities in the material allow the magnetic flux to leak and the particles will be attracted to these areas forming indications which are then evaluated to determine the nature of the defect.