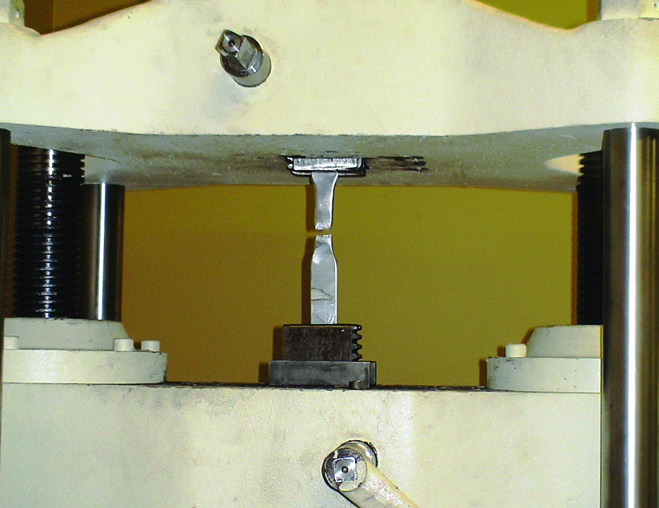

Tensile & bend testing – Per ASME, AWS, CSA and ASTM standard

We are equipped with two traction machines having capacities of

60, 000 lbs and 120,000 lbs respectively as well as numerous fixtures for performing bending tests.

Charpy impact testing – ASTM E23

Standardized test to determine the amount of energy absorbed during fracture. Test temperature can be as low as -320°F.

Hardness testing

Brinell ASTM E10, Rockwell ASTM E18, Micro-hardness ASTM E384, Macro-hardness Vickers ASTM E92.

Abrasion resistance testing

Resistance to abrasion of metallic materials is evaluated using a method entitled «Dry Sand/Rubber Wheel Abrasion Test» (ASTM G65). A load is applied to the specimen using a rubber wheel of known hardness.

Metallurgical analysis – In laboratory or on site

Our in-house laboratory can assess metallographic, chemical and mechanical properties of materials. Mequaltech’s leading edge equipment allows us to provide the following services:

- photographic and macrographic reproduction;

- optical microscopy;

- thickness measurement of coatings;

- corrosion evaluation & analysis;

- evaluation of grain size and carburization;

- In situ metallographic evaluation;

- failure analysis.